The rapid shift to electric vehicles (EVs), grid-scale energy storage, and advanced consumer electronics is powered by lithium-ion batteries. Prized for their high energy density and rechargeability, these batteries are the cornerstone of modern technology. However, concentrating so much energy in a small space introduces inherent risks. Ensuring the battery safety of these products is paramount for building consumer trust and enabling mass adoption. This guide explains the core principles of safety of lithium ion batteries, from the raw materials inside a single cell to the sophisticated systems in an EV pack, and looks at the future of safer battery technology.

Lithium-Ion Battery Hazards: Dendrites & Thermal Runaway

The primary safety concerns in a lithium-ion battery stem from two main failure mechanisms: thermal runaway and dendrite growth.

1. Thermal Runaway

Thermal runaway the most dangerous failure mode, where a battery cell enters an uncontrollable, self-heating state. The process is a chain reaction driven by heat-releasing chemical reactions. It often begins with the breakdown of an internal component called the SEI layer, which then allows the anode to react with the flammable liquid electrolyte, generating heat and combustible gases. The critical point of no return occurs at higher temperatures when the cathode material itself becomes unstable and breaks down, releasing its own internal supply of highly reactive oxygen. This event is what makes lithium-ion fires so perilous; the combination of fuel (electrolyte vapors) and an internal oxidizer (oxygen) inside a sealed cell can lead to violent venting, fire, and explosion.

2. Lithium Dendrites

Lithium dendrites are microscopic, needle-like structures of metallic lithium that can form on the anode, especially during fast charging or charging at low temperatures. These "dendrites" can grow long enough to puncture the separator, the membrane that keeps the positive and negative electrodes apart. This creates an internal short circuit, which can trigger the catastrophic thermal runaway cascade.

Safer Battery Materials: LFP vs. NCM Cathodes

The choice of materials is fundamental to mitigating these inherent risks.

1. Safer Cathodes

The most significant safety improvement comes from the choice of cathode material. While high-energy NMC and NCA cathodes offer greater range for EVs, they are more prone to releasing oxygen when they overheat. In contrast, Lithium Iron Phosphate (LFP) cathodes have an exceptionally stable olivine crystal structure. This structure is highly resistant to breaking down and releasing oxygen, even under severe abuse. This makes LFP batteries significantly safer and far less likely to experience a violent thermal runaway. A battery safety data sheet for an LFP battery will reflect this superior thermal stability.

2. Advanced Anodes & Electrolytes

While graphite is the standard anode, researchers are developing silicon-graphite composites to increase energy capacity while controlling the material's tendency to swell. The ultimate goal, however, is to eliminate the root causes of fire. This is driving innovation in non-flammable or solid-state electrolytes. By replacing the flammable liquid with a stable gel or a solid ceramic/polymer material, the "fuel" component of a battery fire can be completely removed, drastically improving the safety of lithium ion batteries.

Cell-Level Safety Design

To manage inherent chemical risks, each battery cell is built with several internal safety mechanisms designed to prevent a catastrophic failure.

1. Internal Safety Mechanisms

· Shutdown Separators: The membrane between the electrodes is designed to melt and close its pores at a specific temperature (around 135°C), stopping the electrochemical reaction and current flow.

· Pressure Relief Vents: If internal pressure from gas buildup becomes too high, a scored vent is designed to burst open, releasing the gas in a controlled manner to prevent the cell from exploding.

· Current Interrupt Devices (CIDs): Often found in cylindrical cells, a CID is a pressure-activated fuse. If pressure builds, it physically breaks the electrical circuit inside the cell, stopping the flow of current.

2. Abuse Resistance Tests

Batteries for demanding applications are rigorously tested to ensure they can resist abuse. This includes nail penetration and crush tests to simulate an internal short circuit and impact, as well as testing for thermal stability when overheated.

Module and Pack-Level Safety

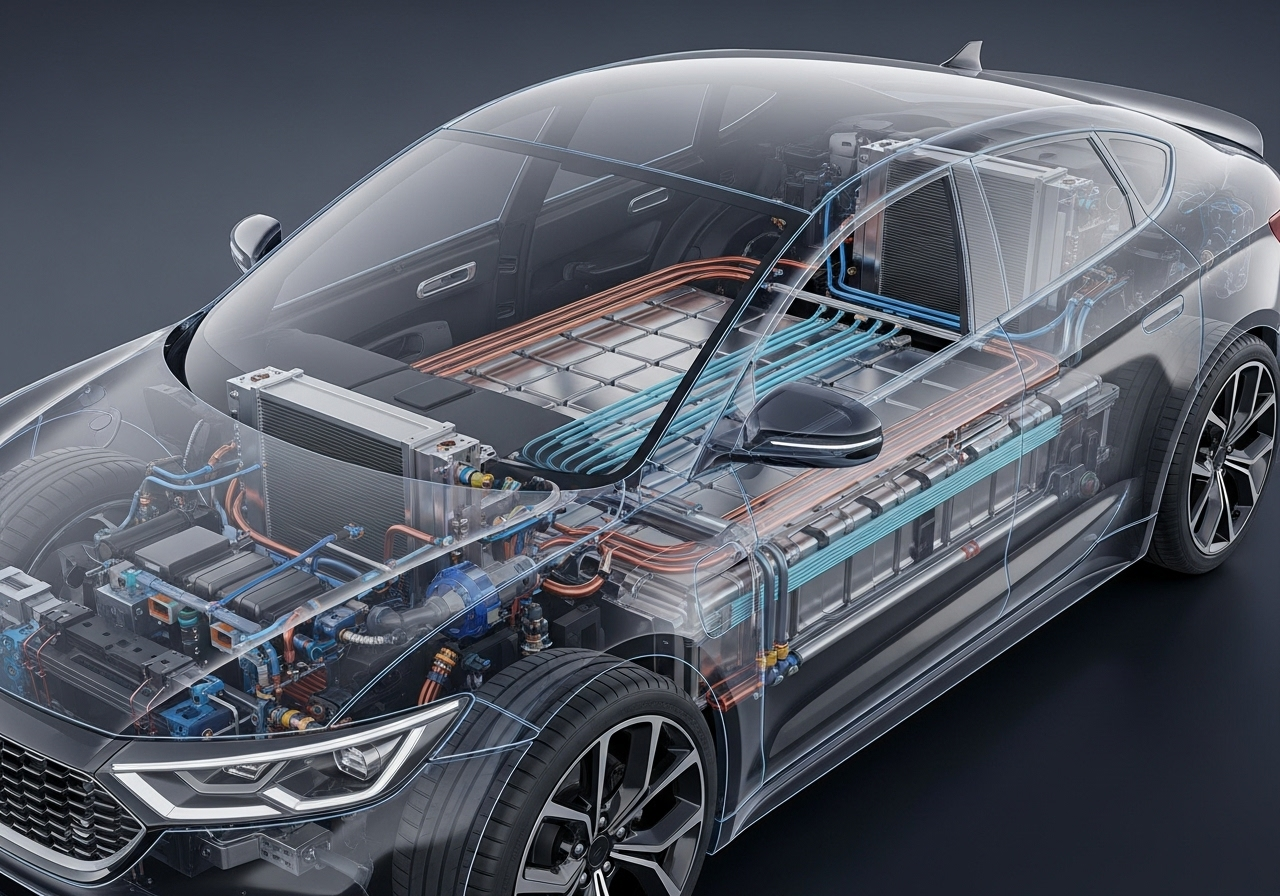

Individual cells are assembled into modules and then into a full battery pack. This pack is protected by multiple layers of electronic and mechanical safety systems.

1. Electrical Protection

The Battery Management System (BMS) is the "brain" of the pack. It continuously monitors the voltage, current, and temperature of every cell. If it detects a problem like overcharging or overheating, it can disconnect the battery to prevent damage. The BMS also performs cell balancing to ensure all cells age evenly, which is crucial for safety and longevity.

2. Thermal Management

The BMS works with a Thermal Management System (TMS) to keep the battery in its optimal temperature range (15-35°C). In EVs, this is typically an active liquid cooling system that circulates coolant through plates attached to the cells, removing heat and dissipating it through a radiator. The pack also incorporates spacing and fire-retardant insulation between cells to slow or stop the spread of a thermal event from one cell to its neighbors.

3. Mechanical Protection

The battery pack is housed in a robust enclosure, typically made of high-strength steel or aluminum. This enclosure is a structural part of the vehicle, designed to withstand severe crash impacts and prevent intrusion that could crush the cells inside. It is also sealed to protect against water and dust and includes channels to safely vent hot gases away from the vehicle cabin in the event of a failure.

Future Trends in Battery Safety

The future of battery safety lies in developing smarter materials and systems.

1. Solid-State Battery Safety

The most anticipated innovation is the solid-state battery, which replaces the flammable liquid electrolyte with a solid material. This dramatically reduces the risk of fire. However, challenges remain, including preventing dendrite growth through the solid material and ensuring stable contact between the solid components during expansion and contraction.

2. AI for Battery Hazard Detection

A paradigm shift is occurring through the use of Artificial Intelligence (AI) and machine learning in the BMS. Instead of reacting to failures, an AI-powered BMS can predict them. By analyzing subtle changes in voltage and temperature, AI algorithms can identify the early warning signs of dendrite formation or other faults, allowing the system to take preventative action—like reducing power—long before a dangerous situation develops.

Great Power Battery Safety Innovations: UL-Certified Cells

Putting these principles into practice, Great Power is at the forefront of manufacturing safer batteries. Great Power emphasizes a holistic approach to safety, from chemical selection to rigorous testing. A key indicator of this commitment is achieving multiple UL certifications, including UL 1973 for stationary energy storage, UL 1642 for lithium cell safety, and UL 9540A for evaluating thermal runaway and fire propagation risks.

These certifications reflect compliance with some of the most rigorous battery safety standards in the industry. To earn them, batteries must pass a wide range of demanding tests, such as:

· Overcharge and short-circuit protection trials.

· Crush, impact, and nail penetration tests.

· Thermal abuse and fire exposure tests.

By designing cells that meet and exceed these standards, Great Power provides verified layers of protection against mechanical, electrical, and thermal hazards—making them a trusted partner for safety-critical energy applications.

Great Power is also making strong progress in solid-state battery development. Its latest cells demonstrate over 10,000 cycles of life, energy efficiency exceeding 96%, and have passed thermal runaway propagation tests, highlighting major improvements in both safety and performance.

Conclusion

The safety of lithium ion batteries is not dependent on a single feature but is the result of a complex, multi-layered system. It starts with inherently stable chemistry like LFP, is reinforced by cell-level safety devices, and is actively managed by sophisticated electronic and thermal systems at the pack level. Innovations in solid-state technology and AI promise an even safer future. As technology continues to advance, a deep commitment to this system-wide safety philosophy is what enables consumer trust and powers our electrified world.

Date:2025.07.18

Date:2025.07.18

Views: Loading

Views: Loading