The modern world is powered by lithium-ion batteries (LIBs), from smartphones to electric vehicles (EVs) that are transforming our transportation sector. However, conventional LIBs—limited by flammable liquid electrolytes and nearing their theoretical energy limits—present growing challenges in safety, performance, and durability. This has ignited a global race to develop the next-generation energy storage solution: the ASSB battery technology.

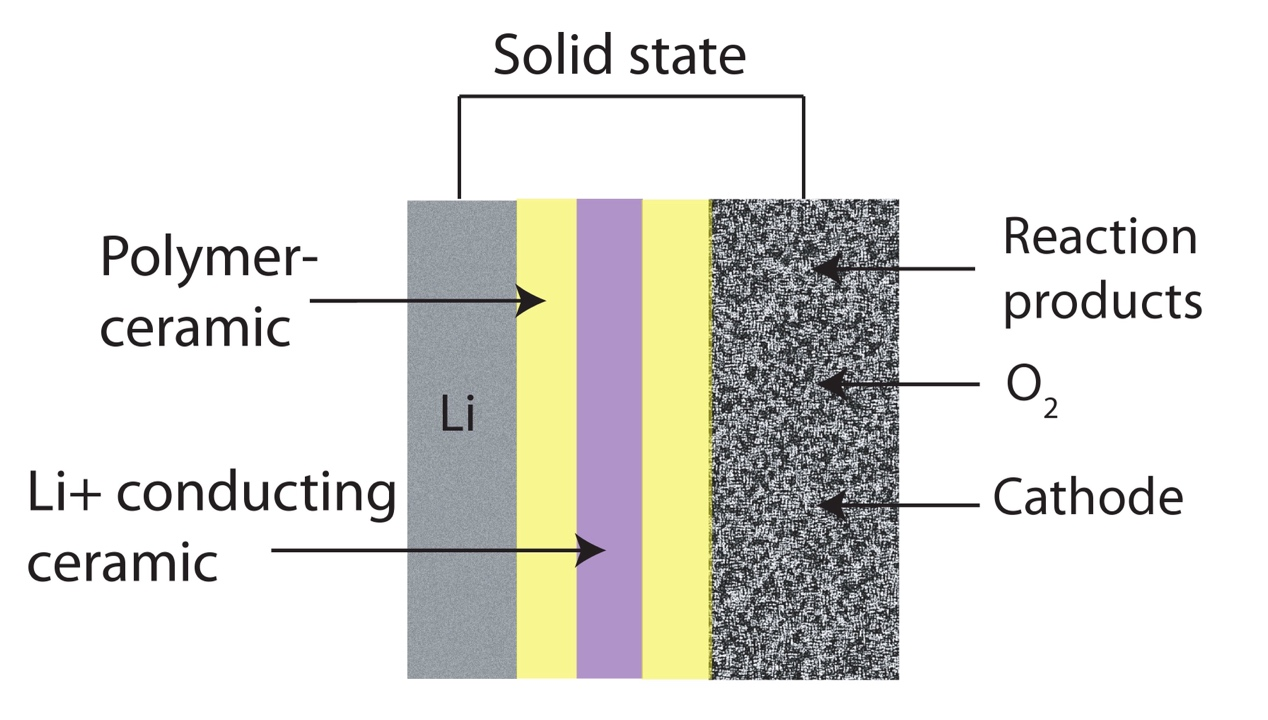

An ASSB stands for an all-solid-state battery, it is an electrochemical cell in which the cathode, anode, and electrolyte are all solid or gel-like materials. Unlike traditional batteries that use a flammable liquid electrolyte, ASSBs rely on a solid electrolyte that conducts lithium ions while acting as a physical separator, dramatically enhancing safety. By enabling the use of pure lithium metal anodes and more compact designs, ASSBs offer the potential for significantly higher energy density, improved thermal stability, and longer cycle life. As such, ASSB technology promises a paradigm shift in energy storage—one that could redefine the future of EVs, electronics, and grid infrastructure.

How ASSB Battery Technology Works

An ASSB is composed of three primary solid components: a cathode, a solid electrolyte, and an anode.

· Cathode (Positive Electrode): This component stores lithium ions and often uses the same advanced materials as state-of-the-art LIBs, such as NMC (Lithium Nickel Manganese Cobalt Oxide), leveraging mature supply chains.

· Solid Electrolyte (SE): The core of the battery, this is a thin layer of ceramic, sulfide, or polymer material. It must be an excellent conductor of lithium ions but a strong insulator of electrons.

· Anode (Negative Electrode): This stores lithium ions when the battery is charged, with the ultimate goal being the use of a high-energy pure lithium metal anode.

Charge & Discharge Process

During charging, an external voltage pulls lithium ions (Li⁺) from the cathode, which then migrate through the solid electrolyte's structure to the anode. During discharge, the process reverses, with ions flowing back to the cathode, creating an electric current to power a device.

A critical aspect of solid electrolyte vs liquid systems is the interface. A liquid perfectly "wets" the electrode surface, ensuring excellent contact. In an all-solid system, achieving this contact between two rigid surfaces is a major challenge, and any gaps can create high resistance, limiting power and charging speed. However, a key advantage of the solid electrolyte is dendrite suppression. A mechanically strong SE acts as a physical barrier to block the growth of lithium dendrites—needle-like structures that can cause short circuits and fires in liquid-based batteries.

Key Advantages of ASSB Battery Technology(Technical Explained)

The benefits of ASSBs are interconnected, creating a compounding effect that could set new performance standards.

1. Higher Energy Density Batteries

The primary driver is the enablement of a lithium metal anode, which has a capacity ten times greater than graphite. This, combined with more compact cell designs (like bipolar stacking), could dramatically increase the energy stored per unit of weight (Wh/kg), with some projections as high as 900 Wh/kg.

2. Superior Safety

ASSBs are a form of non-flammable battery technology. Eliminating the flammable liquid electrolyte is the main safety advantage, significantly reducing the risk of fire and thermal runaway. The solid electrolyte's strength in preventing dendrite-induced short circuits further enhances this safety profile.

3. Longer Cycle Life

The stable solid-solid interface minimizes the parasitic reactions that degrade electrodes in LIBs. This allows for thousands of charge-discharge cycles with minimal capacity loss, with prototypes demonstrating over 6,000 cycles and 95% capacity retention after 1,000 cycles.[1]

4. Wide Temperature Range Batteries

Solid electrolytes are more stable at high temperatures (>60°C) and do not freeze at low temperatures, unlike liquid electrolytes. This allows for better performance in extreme climates where LIBs struggle.

5. Greater Design Flexibility

The solid construction eliminates the need for bulky containment hardware for liquids, allowing for more compact, lightweight, and even flexible battery designs suitable for wearable technology or medical implants.

Major Technical Challenges of ASSBs

Despite their promise, significant technical hurdles stand in the way of mass commercialization.

1. High Interfacial Impedance

Achieving perfect, uniform contact between solid electrodes and the solid electrolyte is extremely difficult. Microscopic gaps create high resistance (impedance), which throttles the battery's power and charging speed.

2. Lithium Dendrite Formation

While suppression is a key goal, the ASSB dendrite problem persists. Under fast charging conditions, dendrites can still grow through physical defects or grain boundaries in the solid electrolyte, leading to short circuits.

3. Low Room-Temperature Ionic Conductivity

Many solid electrolyte materials, especially oxides and early polymers, have poor ionic conductivity at ambient temperatures and require heating to 60-85°C to work effectively, which adds complexity and energy cost.

4. Complex and Costly Manufacturing

ASSB manufacturing is currently far more expensive than for LIBs. Processes like high-temperature sintering for ceramics are energy-intensive, and highly conductive sulfide materials are sensitive to moisture, requiring costly, ultra-dry production environments.

5. Cycle Degradation and Reliability

Electrodes naturally swell and shrink during cycling. In a rigid solid system, this "breathing" creates immense mechanical stress that can cause the electrolyte to crack or the interfaces to separate, leading to battery failure.

Technical Routes & Research Progress

Researchers are pursuing several pathways to overcome these challenges, focusing on system-level integration and interfacial engineering.

A key strategic division is between true all-solid-state and semi-solid-state batteries. Semi-solid systems are a pragmatic compromise, using a small amount of liquid or gel electrolyte to solve the interfacial contact problem while still being safer than conventional LIBs. Many of the first "solid-state" batteries reaching the market are semi-solid.

The choice of electrolyte material involves a trade-off between sulfide vs oxide solid electrolytes vs polymers:

· Sulfide Electrolytes: Offer the highest ionic conductivity, rivaling liquids, and are soft enough for good contact. However, they are chemically unstable and highly sensitive to moisture.

· Oxide Electrolytes: Are extremely stable chemically and in air. But they are brittle, making good contact difficult, and require high-temperature processing.

· Polymer Electrolytes: Are flexible, easy to process, and scalable. However, they suffer from very low conductivity at room temperature and are not compatible with high-voltage cathodes.

To solve these issues, researchers are focused on interface engineering, developing ultra-thin protective coatings for electrodes and creating composite electrolytes that combine the conductivity of ceramics with the flexibility of polymers.

Market Landscape & Outlook

The race to commercialize ASSBs involves a mix of agile startups, incumbent giants, and strategic automakers. Key players include pure-play developers like QuantumScape and Solid Power, major battery manufacturers like Samsung SDI and CATL, and auto OEMs like Toyota and Volkswagen, who are deeply invested in the technology.

Forecasts for the ASSB market size 2030 vary widely but all point to explosive growth, with estimates ranging from around $1 billion to over $15 billion.[2] The EV solid-state battery timeline is expected to be phased:

· 2024-2027: Early demonstration vehicles, often with semi-solid batteries.[3]

· 2028-2030: Beginning of mass production, with some forecasts suggesting 10-15% of new EVs could feature the technology by 2030.[4]

· Post-2030: Widespread adoption in mainstream vehicles as costs come down.[5]

While EVs are the primary market, applications also include long-lasting consumer electronics, medical implants, aerospace, and grid-scale energy storage.

Great Power ASSB Plans: Our Solid-State Battery Progress

While much of the industry is still in the experimental phase, Great Power has already made significant strides in bringing solid-state battery (ASSB) technology toward commercial readiness. Our development efforts focus on oxide-based solid electrolytes, balancing safety, manufacturability, and performance for real-world applications.

We have engineered a practical solid-state cell architecture using advanced materials and scalable processes, tailored for next-generation mobility and specialized electronic devices.

Key Innovations and Features

· Oxide Composite Electrolyte System: A chemically stable ceramic-based electrolyte enhanced with functional additives to ensure high ionic conductivity and robust structural integrity.

· Improved Wet-Coating Process: Enables consistent interface quality between electrodes and electrolyte—critical for reliable performance and scalable production.

· Integrated Safety Mechanisms: From intrinsically non-flammable materials to high thermal conductivity additives that prevent local overheating, safety is built into every layer.

Performance Highlights

· Energy Density: Up to 280 Wh/kg, enabling lightweight and compact designs.

· Cycle Life: Over 600 full charge-discharge cycles with strong capacity retention.

· Operating Range: -20°C to 85°C, suitable for demanding and extreme environments.

Application Focus

· Wearable and Medical Electronics: Reliable power for compact, durable, and high-safety devices.

· Low-Altitude Aerial Vehicles: eVTOL, drones, and aviation systems requiring high energy-to-weight ratios.

· Electric Transport: From electric two-wheelers to commercial and marine platforms.

Great Power continues to accelerate R&D and pilot production of solid-state batteries, building the foundation for large-scale deployment across multiple sectors.

Conclusion

All-solid-state battery (ASSB) technology represents a transformative leap in energy storage—offering higher energy density, improved safety, and longer service life compared to conventional lithium-ion systems. As the industry overcomes critical challenges in interface engineering and manufacturing scalability, ASSBs are poised to unlock the next generation of electric mobility, aviation, and smart electronics.

At Great Power, we are not waiting for the future—we are building it. With solid progress in oxide-based ASSB development and a clear roadmap to commercialization, we are combining innovation with scale to bring safer, smarter, and more powerful energy solutions to the world.

Date:2025.07.18

Date:2025.07.18

Views: Loading

Views: Loading